One of the questions I am frequently asked is, “How can I make soap without lye?”

I completely understand it can be scary to work with sodium hydroxide and potassium hydroxide as they are caustic chemicals that need to be handled carefully.

This keeps many people away from experiencing the wonderful craft that is soapmaking.

The truth is, soap cannot be made without lye. However, a pre-made soap base known as melt and pour can be used to create custom soap bars.

What Is Soap?

Soap is the salt of a fatty acid.

When fatty acids such as those contained in natural oils and fats, react with an alkali such as sodium hydroxide it produces a salt (soap) and glycerine. Sodium hydroxide is used to make solid soap and potassium hydroxide is used to make soft and liquid soaps. The chemical process of making soap is called saponification.

It is believed through an ancient legend, that the word ‘soap’ came from a place called Mount Sapo in Rome, where burnt animal offerings were made. Rainwater leached lye from the ashes which mixed with the rendered animal fat and washed downstream. Roman women washing their clothes in the Tiber river nearby observed that there was a deposit of a waxy substance that lathered and cleaned their clothes well.

Throughout the world, in different cultures, the making of soap has advanced and developed in many ways. It has become a necessity for hygiene and cleanliness as well as a cherished craft and creative outlet for artisan soapmakers.

What is Lye?

Lye typically is used to refer to sodium hydroxide and caustic potash is used to refer to potassium hydroxide. Both of these chemicals are highly corrosive. When dissolved in water, lye solution is alkaline and reacts with acids. Commercially, other than in the manufacture of soap, sodium hydroxide is used in drain and oven cleaners.

The Material Safety and Data Sheet (MSDS) for sodium hydroxide lists specific safety measures that need to be carried out to ensure the safety and protection of the user.

As a beginner to soapmaking, this can be intimidating. Although, once safety measures are always practised, making soap from scratch can be a safe and enjoyable experience.

If you would like to see how a simple cold-process soap is made using lye, you can view my post on Soapmaking For Beginners.

What Is Melt And Pour Soap?

The melt and pour process is exactly what the name implies – melting and pouring. The pre-made soap base is made with ingredients that allow it to melt and re-solidify. It has already been saponified and cured, which means there are no caustic chemicals in it to handle.

Once melted, other ingredients can be added to customize the soap and add to its properties. It is then poured into a mould and left to harden.

Some additives that can be put in the soap are:

- Fragrance or essential oils

- Herbs

- Clays

- Colourants

- Moisturizers

- Exfoliants

There are many melt-and-pour soap bases on the market. They come in a variety of colours and are made with different additives such as shea butter, goat milk, aloe vera and activated charcoal, just to name a few.

Choose a soap based on your preference.

Adding Fragrance

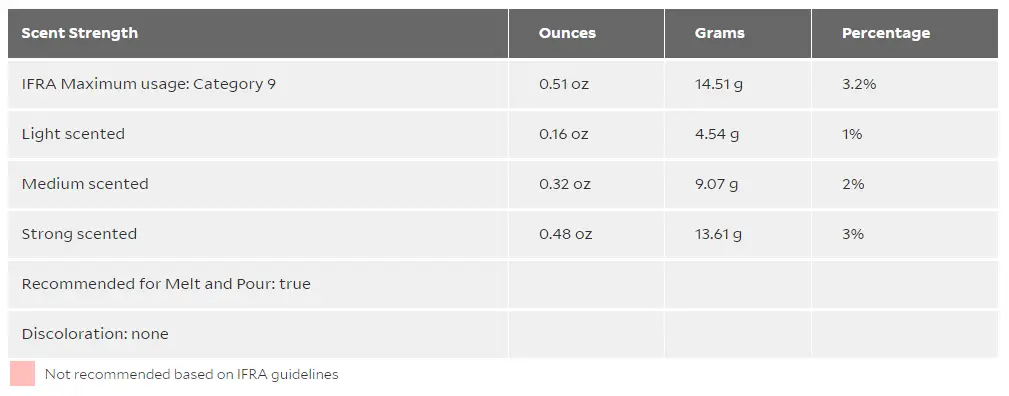

Depending on how strong you would like the fragrance to be in melt and pour soap, some suppliers of fragrance oils provide a fragrance calculator or guide to help determine how much fragrance should be used. The chart below is from the fragrance calculator on the Bramble Berry website for the Grapefruit Bellini fragrance oil I used to make the soap in this post. Based on this chart, I opted to use 0.4 ounces of fragrance to one pound of soap base.

Also, the flash point of the fragrance or essential oil being used in the recipe should be taken into consideration.

The flash point is the temperature at which the oil can ignite or combust if exposed to an open flame. At this temperature, the composition of the scent changes as it vaporizes. Although a thermometer is not mandatory to make soap without lye, it is advisable to check the flash point of the fragrance you intend to use. Most reputable companies list the flash point temperature either on the label of the fragrance package and/or on their website.

The melting point of most melt and pour soap bases is around 125°F. Provided that the soap is not allowed to overheat past melting, it should reach a temperature of around 150°F. Working with this range, it is best to choose a fragrance or essential oil that does not have a low flash point since the melt and pour process requires heating.

In the soap recipe presented below, the temperature of the soap after melting was 148.3°F.

Adding Colour

As with fragrances, always use pigments that are skin-safe in your soaps. Avoid using things like crayons or dyes used for candles to colour soap. Check with your supplier to ensure that the colourant you intend to use is safe to use in soap. There are many micas, pigments, oxides, liquid and block dyes that are available.

Also, natural ingredients can contribute to the colour of soap such as the cocoa powder used in this Chocolate Soap recipe. If you would rather use natural ingredients, feel free to experiment with pigmented clays and powders such as turmeric in your soaps.

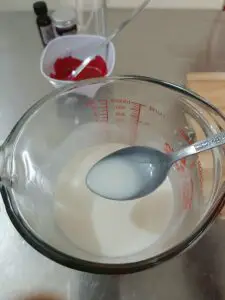

It is best when adding powdered colourants to the melted soap, to dissolve it first in one or two tablespoons of isopropyl alcohol as shown in the recipe below. This ensures that there are no clumps and there is better distribution of the colour.

Benefits of Making Soap Without Lye

Making melt and pour soap is not only fun to create a variety of colours, designs and fragrances, but there are some other benefits to using this process. The melt and pour method of soapmaking;

- It is quick and simple

- It is great for beginners

- Requires less equipment than soap made from scratch

- Requires no curing period

- Does not cause fragrances to morph

- It is a good project for children (with supervision)

- It is much safer than making soap with lye

One major disadvantage to making soap with a pre-made soap base is that not all the ingredients and chemicals in the base may be known. It is best to purchase your base from a reputable supplier that is transparent about what their soap bases contain.

There are melt and pour soapmaking kits available online from Amazon such as this one.

Nurture Soap and Bramble Berry also have similar kits available.

Many other soap suppliers as well as hobby stores sell soap base by the pound. Do some research to see if there is a local supplier near you.

Here in Trinidad, three local suppliers are:

Soap Recipe To Make Soap Without Lye

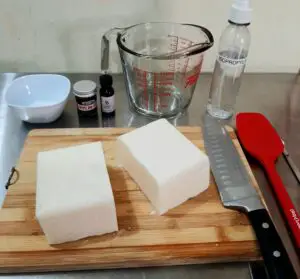

Equipment Required

- Microwave or Double Boiler

- Heat-safe container

- Knife to cut the soap base

- Soap Mould

- Container to mix colourant

- Isopropyl alcohol

- Spoon or silicone spatula

- Candy or Digital Thermometer (optional)

Soap Ingredients

- 1 lb melt and pour soap base

- 0.4 ounces of fragrance oil

- Colourant (mica or pigment)

The fragrance oil I used is Grapefruit Bellini by Bramble Berry and the colourant is Trial By Fire by Nurture Soap.

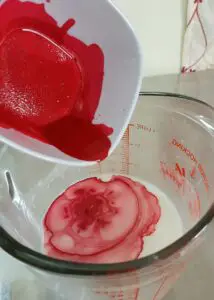

To about 1 teaspoon of colourant, add 1 or 2 tablespoons of isopropyl alcohol into a container and mix well until there are no clumps.

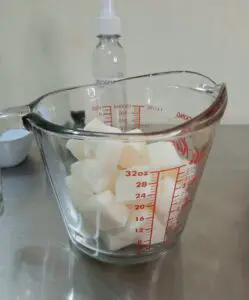

Next, cut up the soap base evenly sized from 1/2″ or 1″ cubes and place them in the heat-proof container.

If using the double-boiler method, place the container with the soap in the heated double-boiler and stir it occasionally just until all the soap cubes are melted.

If you are using a microwave, place the container in the microwave and let it run on full power for 30-second intervals. At every interval remove it from the microwave and stir the soap. Keep repeating this step until the soap is dissolved.

We do not want to overheat the soap as this can cause scorching which can change the colour and contribute to a burnt smell. At the last interval put it in for a shorter time such as ten seconds, if necessary, until the soap is melted.

Remove the liquified soap from the heat.

This next step is optional, but I checked the temperature to ensure that it was below the flash point of the fragrance oil I wanted to use. Again, the flashpoint for Grapefruit Bellini as listed on BrambeBerry is 200°F so nothing to worry about there.

Next, add the colourant in small amounts and mix well until the desired colour is achieved.

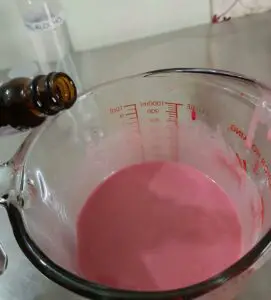

Add the fragrance oil. It is important to stir the soap well for at least 30 seconds to ensure the oil is well-dispersed in the soap to avoid separation.

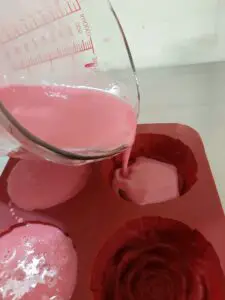

Once everything is well-blended, pour the soap into the mould. Spritz the top of the soap with isopropyl alcohol to remove any bubbles, then allow it to cool fully.

Once cool and solidified, remove the soap from the mould. The soap can be used immediately.

How to Store Your Melt and Pour Soaps

These soap bars are rich in glycerine which is a humectant that draws in moisture from the atmosphere. They tend to sweat and form ‘glycerine dew’ on the surface of the bars, especially in a humid environment. To prevent the soaps from sweating, it is best to wrap them tightly in plastic wrap and store them in a cool dry place.

Many books and courses are available to help you progress on your soapmaking journey.

One of my favourite soapmakers, Jan Berry of the Nerdy Farmwife has a book called Easy Homemade Melt & Pour Soaps available through Amazon on Kindle or paperback.

So here we have a great option to participate in the craft of soapmaking without going through the saponification process. It is quick and easy and can be fun for the whole family.

Let me know, which method of soapmaking you prefer?

As always – Happy Soaping!!! 🙂

Motivated Mom , thank you for the inspiration. It was well needed in my case. Loving the process of melt n pour . Saved me time & money.

Blessings 🍃🫧

Hello Yolan,

You’re welcome. I’m happy to know that it was helpful. Blessings to you as well and happy soaping! 🙂