Castile Soap has been around for centuries. It is a natural soap that is made of 100% Olive oil and it gets its name from Castile, Spain, where it is believed it originated.

There is however, a version called Bastille soap. This soap is composed mostly of olive oil (at least 70%) but it also contains other oils or butters.

Bastille soap is beneficial in that it is gentle and conditioning so it is a good option for people with sensitive skin.

Creamy Shea Butter Bastille Soap

Here is the recipe for a wonderful Creamy Shea Butter Bastille Soap that came directly from the Simple and Natural Soapmaking book by Jan Berry.

This is a great recipe to try as a beginner to soapmaking as it is simple to create and it makes a creamy and moisturizing bar of soap that your friends and family will love.

I used this recipe exactly as is from the book except I scented it by adding 0.9oz of Lavender essential oil at trace.

If you have never made soap before, see my post on Soap Making for Beginners.

Ingredients

- 8 oz (227g) distilled water

- 3.55 oz (101g) sodium hydroxide (lye)

- 21 oz (595g) olive oil (75%)

- 4.5 oz (128g) shea butter (16%)

- 2.5 oz castor oil (9%)

Directions

First suit up with protective gear – eye goggles, long sleeves and gloves. Ensure that inquisitive family members and pets are out of your production area.

In a well-ventilated area, carefully add the sodium hydroxide to the water and stir with a stainless steel spoon to dissolve completely. Avoid inhaling the fumes. Once it is fully dissolved, set it aside to cool.

Next, in a microwave or double boiler, melt the shea butter, only enough to bring it to liquid form, do not overheat.

Add the melted shea butter to the olive and castor oil in the designated mixing bowl and stir to mix.

Slowly pour the lye solution into your oil/butter mixture.

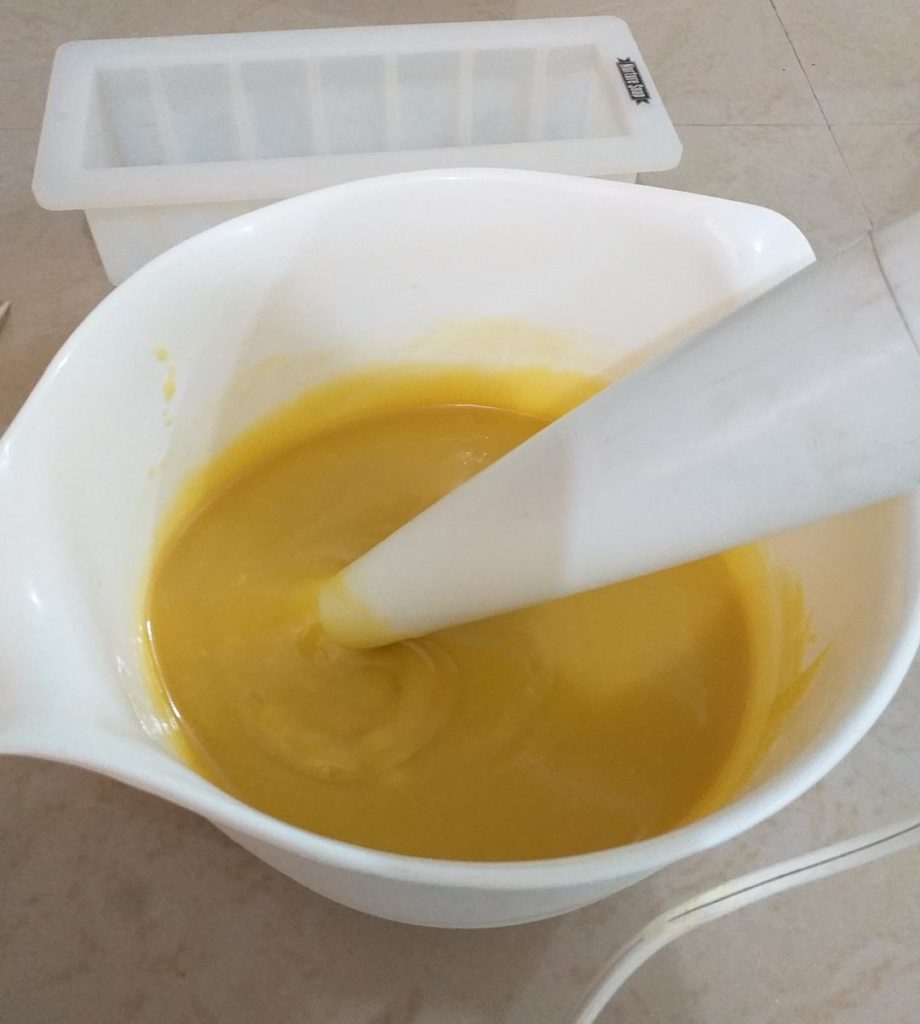

Start blending with the immersion blender occasionally stirring to bring the emulsion to trace.

At this point you may choose to add an essential or fragrance oil to the soap or leave it unscented.

Pour the batter into the prepared mold, cover with a sheet of cardboard or freezer paper and then a towel or light blanket to insulate.

After 24 hours my soap was ready to come out to the mold. If your soap is still somewhat soft, keep it in the mold for 2 or 3 days until it is easy to remove.

Cut the soap into bars according to your preference and set them aside to cure for at least 6 weeks before using.

If you just started on your soapmaking journey this is definitely one I suggest you try.

Happy soaping!

I followed this recipe and added 2.5 teaspoons of French pink clay to the lye solution. I poured the soap in small cavity molds. After 24 hours it is still very soft. I did not wrap it up because I worried the gel phase might effect the color. Will it ever firm up? Or, am I just being impatient?

Hi, Sara.

Cold process soaps made with a very high percentage of olive oil, like castile and bastille can take longer to firm up as olive oil is a soft oil compared to coconut oil, for example.

I would say to leave it in the mold for another two or three days and check the hardness then.

I can’t wait to make this soap. I made homemade soap years ago and fell in love with making different soap recipes. My family enjoys my soaps.

That’s awesome, Lyn. I hope you all like this soap.