Today we will explore how you can create your own column PVC soap mold to achieve beautiful circular bars of soap.

The great thing about using PVC for soap is that it is sturdy, can be cut to fit the size of your recipe and is relatively inexpensive. Although PVC is sensitive to heat, the heat produced during saponification is not sufficient to damage the mold and therefore it can be reused.

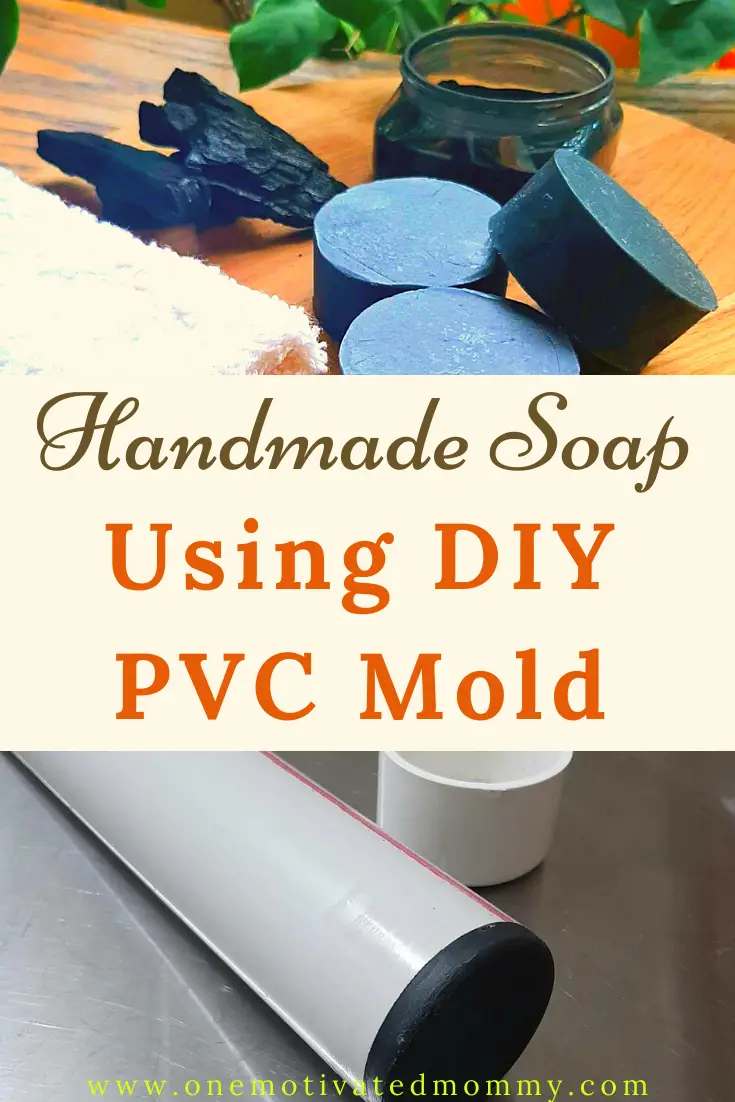

For this recipe, I made an activated charcoal soap with tea tree essential oil, a good soap to cleanse and gently exfoliate oily and acne-prone skin.

I’ve been experimenting with hydroponics at home lately and had some PVC leftover from my last build, but you can check your local hardware or plumbing store and choose the diameter of the pipe you want to use. It is relatively inexpensive and some hardware stores will cut it to the measurement you want.

To calculate the amount of oil needed in your recipe for the size mold you want to use, you need to find the volume of the mold and then multiply by either 0.4 for ounces or 0.7 for grams, depending on which unit of measure you are using. The volume of a cylinder is πr²xh (pi x radius²xheight) – then you multiply by either 0.4 or 0.7.

It may seem complicated, I know. Below is an article by Kenna from Modern Soapmaking that gives a detailed explanation of this formula and how to size your recipes to fit your regular or irregular-shaped molds.

Remember too that you can use a soap calculator to resize any soap recipe to fit your mold or create your own.

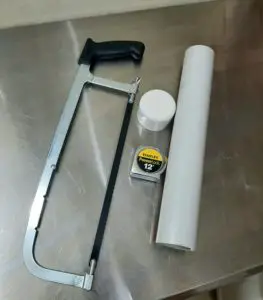

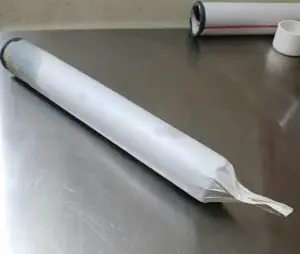

For this project, I used a 2-inch PVC pipe and a 2-inch end cap with freezer paper to line the inside. The pipe was washed and allowed to dry fully before use.

Preparing the Mold.

Measure the PVC and cut it to size, if necessary.

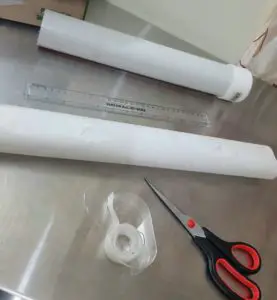

Roll a sheet of freezer paper to fit into the pipe with a slight overlap along the edge. Ensure that the paper also is longer than the mold to have something that you can pull on to get the soap out. Use pieces of tape to stick the edge along the overlapped side before inserting it into the mold.

Once the mold is prepped, we can make our soap.

Ingredients for Activated Charcoal and Tea Tree Soap

- 18 oz Coconut oil

- 6 oz Canola oil

- 4 oz Olive oil

- 2 oz Castor oil

- 2 oz Shea Butter

- 4.89 oz Sodium Hydroxide

- 12.15 oz Distilled Water

- 0.25oz Activated Charcoal

- 1 oz Tea Tree Essential Oil

Directions to Make Activated Charcoal and Tea Tree Soap using PVC Mold.

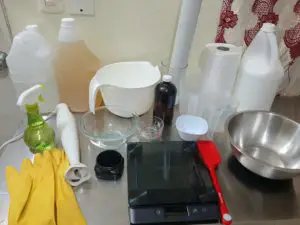

Safety is always paramount in soapmaking! Suit up for safety. Put on gloves, safety eyeglasses and long-sleeved clothing. Ensure that there are no pets or children in the production area.

Assemble all tools and ingredients.

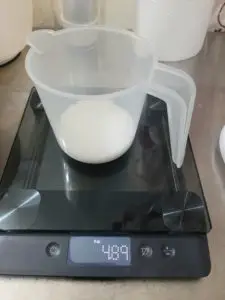

In a heat-resistant or stainless steel container, weigh the water.

Weigh the sodium hydroxide in a dry plastic container.

In a well-ventilated area, add the sodium hydroxide to the water (not the other way around) and stir with a stainless steel spoon to dissolve fully.

The dissolving solution will create fumes, be sure that you do not inhale the fumes. Once fully dissolved, set aside in a safe area to cool to room temperature.

Prepare your other ingredients.

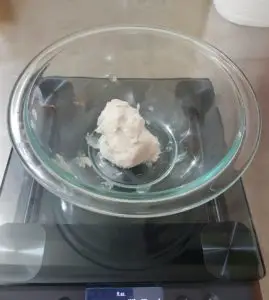

Weigh the shea butter in a heat-proof or microwaveable container.

Using a microwave oven or double-boiler method, melt the shea butter.

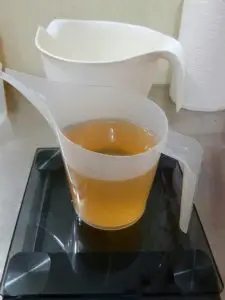

Next, weigh the individual oils and add them to the mixing bowl.

Note, where I live in the Caribbean, coconut oil is always liquid at room temperature – if it is solid in your location, you will have to melt it before adding it to the mixing bowl.

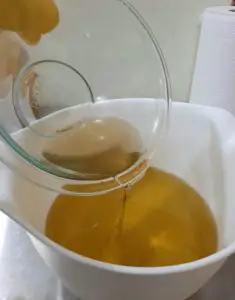

Add the melted shea butter to the mixing bowl with the oils.

Weigh the activated charcoal.

In a glass container, weigh the tea tree essential oil.

Now you are ready to assemble the ingredients to make your soap.

Very carefully add the activated charcoal to the mixing bowl. Be careful not to dump it into the oils as the fine powder can escape into the air and you may breathe it in.

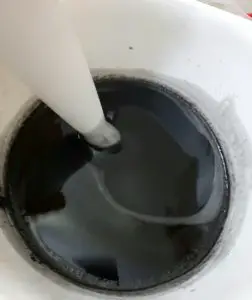

Using the immersion blender, gently push the powder down into the oils to submerge before blending it in at a low speed.

Just blend enough to incorporate it fully.

Next, add the lye solution carefully to the mixture.

Blend with the stick blender to an emulsion, then add the tea tree essential oil.

Using alternating pulses and stirring with the immersion blender, bring the soap batter to trace or to where the batter creates a trail when drizzled back onto itself.

Carefully, pour the soap into the PVC mold, use a spatula to get the last bit of soap out.

Gently tap the base of the PVC end a few times on the counter or floor to remove any air bubbles in the soap. Then, set aside in an upright position to allow it to solidify for 24 hours.

After 24 hours, remove the end cap from the PVC mold and pull the soap out.

My soap slid out relatively easily. If yours seems a little stuck, you can gently push it from the opposite end to help it out.

Remove the freezer paper and cut the soap into bars using a soap cutter or a kitchen knife.

Set your soap in a safe, ventilated area to cure for 4 to 6 weeks, turning them occasionally to ensure all sides are exposed to the air. After the curing period, you can lather up and enjoy your beautiful, circular activated charcoal and tea tree soap.

Happy Soaping!!! 🙂